OEM ODM Machinery Precision Custom Metal Machined Turned Anodised Milled Lathe Turning Milling Machine Machining Mechanical CNC Bending Aluminum Machining Part

Basic Info

| Model NO. | JHX54 |

| Equipment | 3/4/5 Axis Center Machining |

| Drawing Format | 2D/(Pdf/CAD)3D(Iges/Step/STP)etc |

| Finish | Anodized, Polished, Brushed, Plating etc. |

| MOQ | 1 PCS |

| Monthly Capacity | 100000PCS |

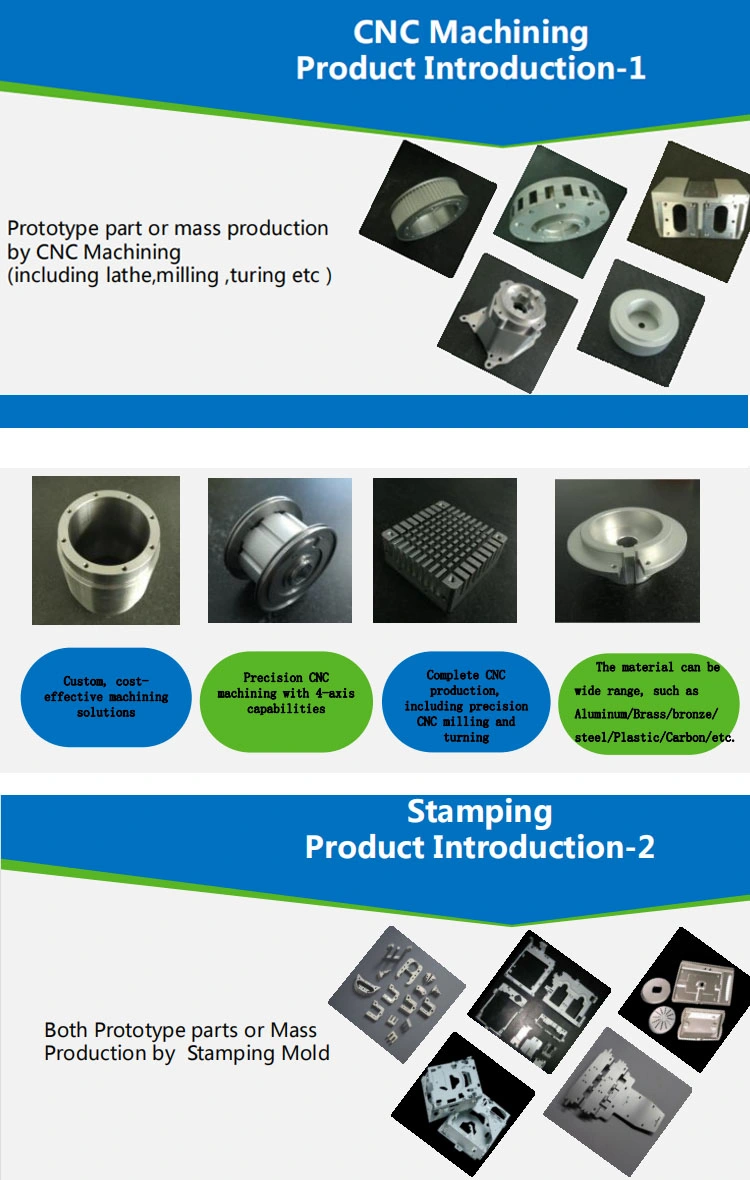

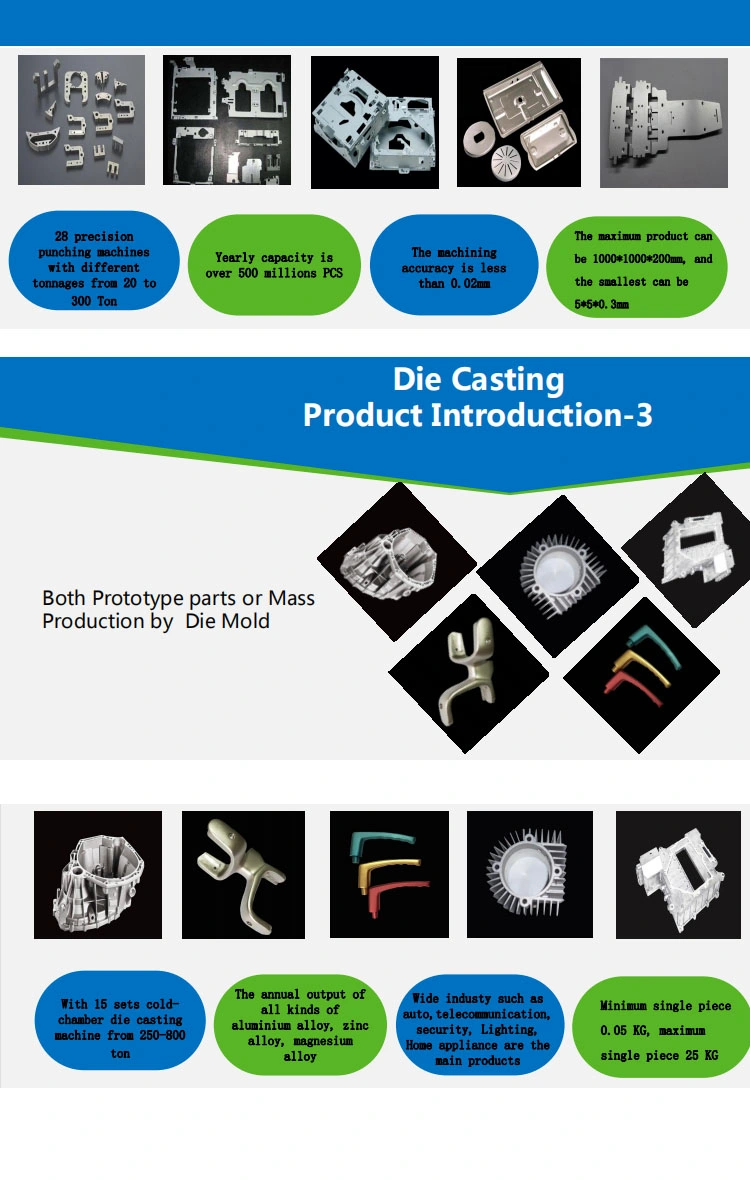

| Process | CNC Turning, Milling, CNC Machining, Lathe |

| Service | Turning Milling Drilling Grinding |

| Micro Machining or Not | Micro Machining |

| Materials | Aluminium/Brass/Stainless Steel/Carbon Steel/ABS |

| Delivery Time | 7-15 Days |

| Quality Control | 100% Inspention |

| Tolerance | +/-0.01 or Custom |

| Advantage | High Precision |

| Color | as Requirement |

| Certificate | ISO 9001 : 2015 |

| Transport Package | Carton or Customized |

| Specification | Customized |

| Trademark | OEM |

| Origin | Shenzhen |

| Production Capacity | 10000 Piece/Month |

Product Description

Customized Precision Spare Part Painting Anodized Aluminum CNC Turning Parts CNC Machining Part for Car Accessories

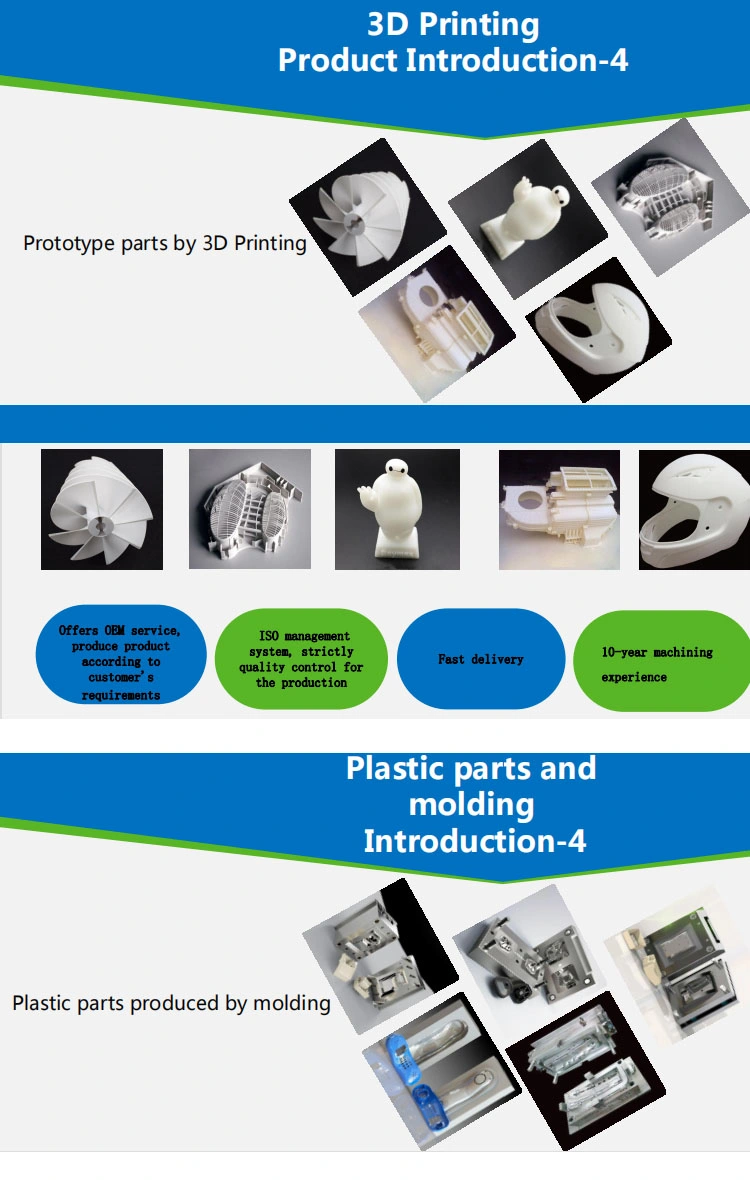

Shenzhen Jiahao Xinda is located in Shenzhen, China, which focuses on CNC machining more than 13 years, including milling, turning, auto-lathe, die casting. Both metal and plastic material are within our capability. We provide one-stop service, from professional design analysis, to free quote, fast prototype, ISO standard manufacturing, to safe shipping and great after-sales services.

During these years, we have win lots of trust in the global market, most of them come from North America and Europe. Now you may have steady suppliers, but still hope you can keep us in the archives to get more market news.

More interests, feel free to send us an inquiry via Contact now, or directly to our email, and then our professional sales manager will get back to you ASAP!

High Quality CNC OEM Machining Supplier | |

Service | CNC Turning, CNC Milling, Laser Cutting, Bending, Spinning, Wire Cutting, Stamping,Electric Discharge Machining (EDM), Injection Molding |

Materials | 1). Aluminum: AL 6061-T6, 6063, 7075-T etc2). Stainless steel: 303,304,316L, 17-4(SUS630) etc3). Steel: 45#,Q235, Q345B4). Titanium: TA1,TA2/GR2,TA4/GR55). Brass: C36000 (HPb62)6). Copper, bronze, POM,Acrylic, PC, etc. |

Surface Treatment | Sandblasting,Anodize color,Zinc/Nickl Plating,Polish |

Processing Technology | CNC machining parts,turning/milling process |

MOQ | 1pcs |

Lead Time | Sample: 3-5 days.Mass Production: within 10-25 days after receiving the deposit. |

Package | 1)pp bags + carton or wooden case2) according to customers' requirements3)negotiable |

Payment Terms | Trade Assurance, T/T/ West Union |

Product Description

Company Profile

Certifications

Exhibition

Packaging & Shipping

FAQ

1.Are you a manufacturer or a trading company?

We are a 12600-square-meter factory located in Shenzhen, China.2.How can I get a quote?Detailed drawings (PDF/STEP/IGS/DWG...) with material, quantity and surface treatment information.

3. Can I get a quote without drawings?Sure, we appreciate to receive your samples, pictures or drafts with detailed dimensions for accurate quotation.4.Will my drawings be divulged if you benefit?No, we pay much attention to protect our customers' privacy of drawings, signing NDA is also accepted if need.5. Can you provide samples before mass production?Sure, sample fee is needed, will be returned when mass production if possible. 6. How about the lead time?

Generally, 1-2 weeks for samples, 3-4 weeks for mass production.

7. How do you control the quality?(1) Material inspection--Check the material surface and roughly dimension.(2) Production first inspection--To ensure the critical dimension in mass production.(3) Sampling inspection--Check the quality before sending to the warehouse.(4) Pre-shipment inspection--100% inspected by QC before shipment.8. What will you do if we receive poor quality parts?Please kindly send us the pictures, our engineers will find the solutions and remake them for you asap.